Supply Chain Management 2026: Processes, Components, and Strategy

The "Amazon Effect" has fundamentally changed global trade. Consequently, consumers now expect two-day shipping and complete transparency. In fact, this growing demand has shifted supply chains from simple back-office functions to critical competitive advantages. Therefore, a strong strategy for 2025 requires more than just cutting costs; it needs resilience, agility, and sustainability.

Defining the Core Concepts

People often confuse Supply Chain Management (SCM) with logistics. However, there is a key distinction. While logistics is simply about moving goods, SCM involves managing the entire flow of data, finances, and products from raw materials to customers. Ultimately, mastering these supply chain processes is crucial for survival in a changing market.

The 5 Core Components of SCM (The SCOR Model)

To handle complex networks, industry leaders depend on the SCOR (Supply Chain Operations Reference) model. Specifically, this model breaks operations down into five distinct phases.

1. Plan

This is the strategic phase. Unlike old spreadsheets, modern planning uses AI-driven predictive analytics to forecast demand more accurately.

2. Source

Next, this component involves procuring materials and choosing vendors. Good sourcing strategies must balance cost and quality, while also maintaining ethical standards.

3. Make

Subsequently, this phase covers manufacturing, testing, and packaging. Being efficient here is vital because it ensures that products reach the market on time.

4. Deliver (Logistics)

This is the most visible part of the chain. For example, it includes warehousing, order management, and transportation.

5. Return (Reverse Logistics)

Finally, this involves handling returns and recycling. Notably, efficient returns processes recover value and improve customer satisfaction.

Top Supply Chain Best Practices for 2025

Recent disruptions have shown how fragile traditional models can be. As a result, forward-thinking managers are adopting the following logistics best practices to build resilience.

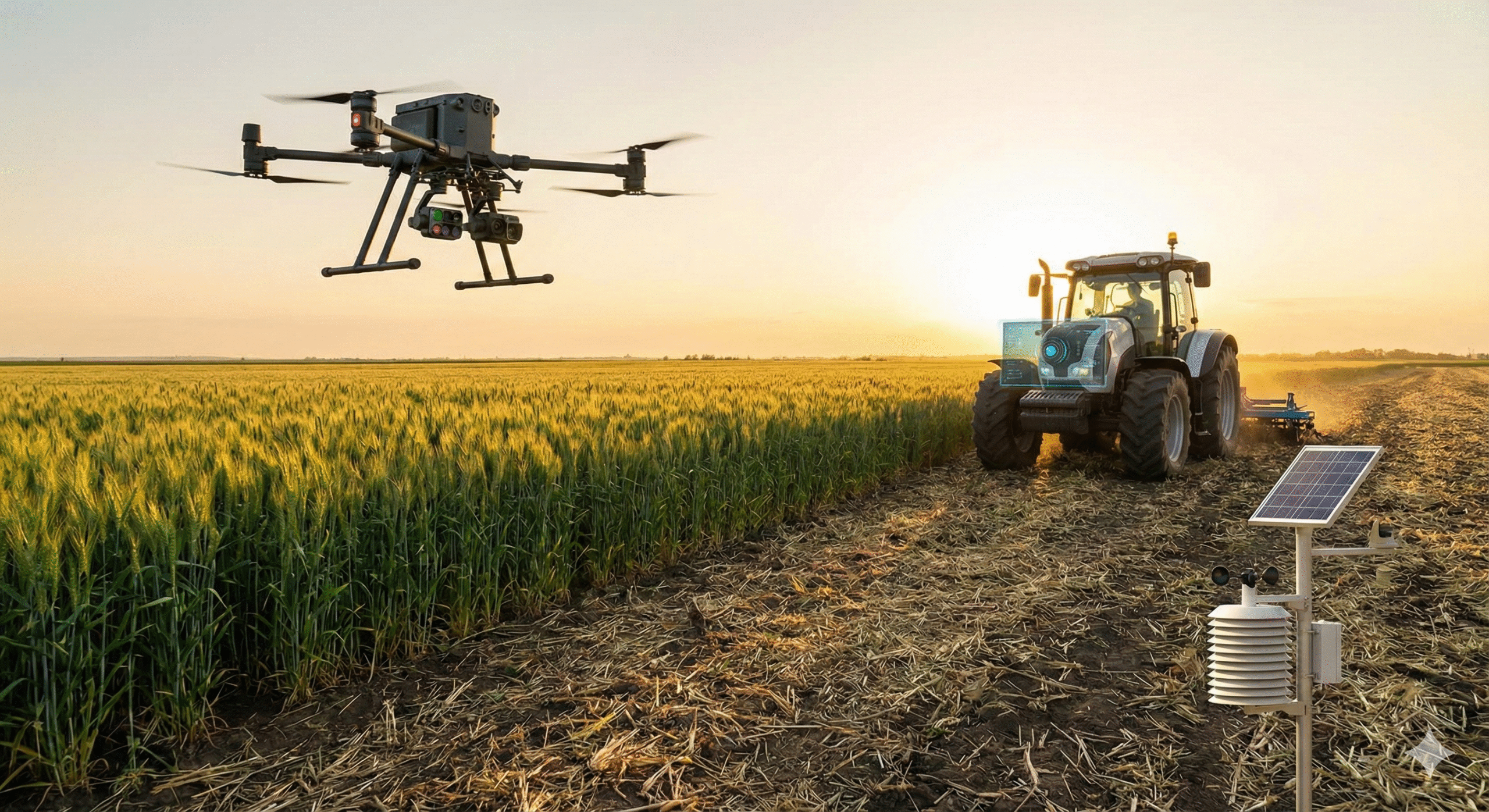

Prioritize Visibility with Technology

Working in silos is risky. Therefore, successful managers use IoT (Internet of Things) sensors to track shipments in real-time. This visibility helps teams react quickly if a port shuts down, thereby keeping all SCM components connected.

Shift from "Just-in-Time" to "Just-in-Case"

Although "Just-in-Time" (JIT) saved on storage costs, it struggled significantly during global shortages. Consequently, the standard for 2025 is a hybrid model. Companies now keep "Safety Stock" for critical items to guard against volatility.

Diversify Your Supplier Base

Furthermore, relying on one source can be dangerous. Many companies are now using a "China Plus One" strategy, having one supplier in Asia and another closer to home. This "Nearshoring" approach lowers geopolitical risks and, additionally, speeds up shipping.

Integrate Sustainability

Moreover, regulators are calling for lower carbon footprints. You can achieve this by optimizing routes and using recyclable packaging. In short, green logistics is no longer just ethical; it has become a financial necessity.

Conclusion

Supply chain management involves balancing efficient processes with smart strategy. Ultimately, the winners in the next decade won’t just be the cheapest options; they’ll be the most adaptable.